Drop-In Liners are most often utilized for galvanizing, plating, and anodizing tanks.

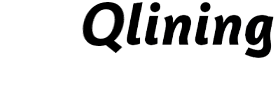

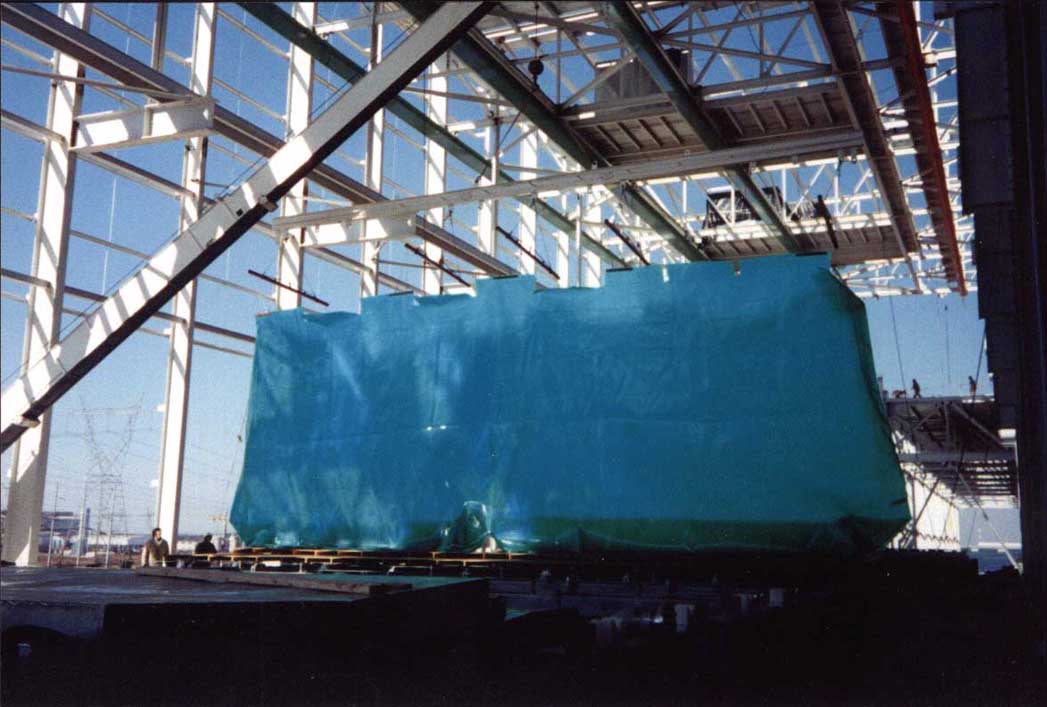

The liner is normally constructed with a flange at the upper edge and attached to the tank with stainless steel clips. A drop-in liner may be fashioned with pipe penetration "boots" or configured to encapsulate baffle walls, weirs, or other internal elements. Although most drop-in liners are utilized in smaller plating tanks, we are proud of the fact that we have furnished and installed curtains 47’ X 9’ X 20’ deep in one piece which were designed for space launch vehicle assemblies. These are the very largest drop-in liners that have been installed anywhere in the US and very likely over the entire planet. We would be pleased to discuss your processing needs. Contact us today to discuss your intended application!

Chemical Resistant PVC Liners

- UV Resistant

- Storage & Process Tanks

- Waste Treatment

- Floor Liners

- Plating Tanks - Cu, Ni, CR, & Precious Metals

- Chrome Plating

- Pickling & Rinsing

Fuel / Oil Resistant UL 1856 Recognized

- Gasoline, JP, Diesel

- MTBE & TAME

- Methanol & Ethanol

- Sodium Hypochlorite

Acid / Alkaline / Hydrocarbon Resistant190

- Plating Baths W / High Brightener Content

- Waste Treatment

- Pulp & Paper Applications

- Alkaline Solutions & Caustic Cleaners

Acid Resistant 145

- Rinse Tanks

- Floor Linings

- Secondary Containment

LFP Liners Available Exclusively Through Witt

Unparalleled 360 Mechanical Strength 500

- Chemically Inert

- Extreme Long Life

- Electroless Nickel Plating eliminates disposable liners. Plate Out is easily brushed off and filtered away. Eliminates Nitric leaching.

- High Temperature Chrome Plating

- Expansion Joints

- Liquor Vats

Acid / Alkaline Resistant 160

- Storage Tank

- Plating Solutions

- Secondary Containment